Hose Clamps - Everything You Need to Know

Figure 1: A hose clamp connects a pipe from a dishwasher to the sink plumbing.

Hose clamps secure and fasten hoses onto fittings or connectors. This creates a tight and secure seal between the hose and the connected component, preventing leaks or disconnections. Hose clamps have a band that encircles the hose and a screw that applies pressure and compresses the hose onto the fitting. This ensures a firm connection and helps to prevent the hose from slipping off or leaking.

Table of contents

- Hose clamp types

- Hose barb fittings

- How to use a hose clamp?

- How to determine the hose clamp size?

- Can hose clamps be used on PEX?

- Where should hose clamps be placed?

- How to tighten a hose clamp?

- How to remove hose clamps?

- What is an everyday use for a hose clamp?

- Do hose clamps loosen over time?

- Why do hose clamps fail?

View our online selection of hose clamps and hoses!

Hose clamp types

There are different types of hose clamps. This section covers the following types:

- Worm gear hose clamp

- T-bolt hose clamp

- Wire hose clamp

Worm gear hose clamp

Worm gear hose clamps, or screw clamps, are the most widely used type of hose clamp. They consist of a band with slots and a screw connected to these slots (Figure 1). As the screw is tightened, the band tightens around the hose, creating a secure seal.

These clamps are easy to use and lower the possibility of damage to soft materials. They are generally used in plumbing and automotive fields.

Figure 2: Worm gear hose clamp design

T-bolt hose clamp

T-bolt hose clamps have a T-shaped bolt that fits into a slot on the band. As the bolt is tightened, the band tightens around the hose. They provide a powerful and reliable clamping force.

T-bolt hose clamps are often used in applications involving high vibration or large hose diameters. Such as, large industrial machinery, heavy trucks, and off-road equipment.

Figure 3: T-bolt design hose clamp

Wire hose clamp

Wire hose clamps, or spring wire clamps, utilize a flexible wire or spring to secure hoses onto fittings. They feature a circular shape formed by overlapping wire ends and are usually made of corrosion-resistant materials like stainless steel.

To use a wire hose clamp, remove the screw and place the wire clamp over the hose. Then, add the screw and tighten it using a screwdriver. Secure the clamp with a nut when it is tight enough.

Wire hose clamps are commonly used in high-pressure applications, offering easy installation and removal. However, they may not last as long as other hose clamp types.

Figure 4: Wire hose clamp

Hose barb fittings

Hose clamps are primarily used to secure a hose to a barbed hose fitting. A hose barb connection consists of a cylindrical fitting with ridges or barbs that securely grip the inside of a flexible hose when inserted. As seen in Figure 5, a hose barb connection can have one or multiple ridges.

Figure 5: Hose barb connections can have multiple ridges (left) or a single ridge at the tip (right).

How to use a hose clamp?

Hose barbed connections provide a snug fit when hoses are slipped over them. However, the only way to mitigate leaking is to fasten a hose clamp over the hose after pushing it over the connection.

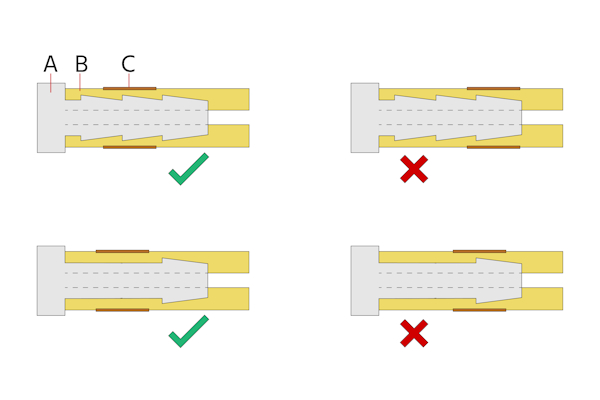

Figure 6 demonstrates the correct and incorrect positions of the hose clamp. It's essential that no part of the clamp overlaps with the ridge closest to the tip of the connection.

Slide the hose clamp (Figure 6 labeled C) onto the hose (Figure 6 labeled B) before sliding the end of the hose over the hose barbed connection (Figure 6 labeled A). Then tighten the clamp using a screwdriver, nut driver, or socket wrench. Tighten the clamp until it securely grips the hose and creates a tight seal. Avoid overtightening to prevent hose damage.

Figure 6: Hose barb connection (A), hose (B), and hose clamp (C). The hose clamp must not overlap with the last ridge closest to the tip of the connection.

How to determine the hose clamp size?

To determine the appropriate hose clamp size, measure the diameter of the hose while it is still connected to the fitting. Since most hose clamps can accommodate a range of diameters, choosing a clamp where the hose diameter falls in the middle of its specified range is advisable.

Can hose clamps be used on PEX?

Yes, stainless steel hose clamps can be used on PEX (cross-linked polyethylene) tubing. However, there are better connection types for PEX, including crimp, push-fit, push-to-connect, and compression.

Where should hose clamps be placed?

Place hose clamps at the ends of the hoses near the fittings or connectors they are securing. This ensures the clamp provides a secure grip on the hose and prevents leaks or disconnections at the critical connection points.

How to tighten a hose clamp?

Use a screwdriver or an appropriate tool to turn the screw or bolt on the hose clamp clockwise. Continue tightening until the clamp firmly holds the hose in place and prevents leaks or slippage.

How to remove hose clamps?

To remove a hose clamp, loosen the screw or bolt by turning it counterclockwise using a screwdriver. Once sufficiently loosened, slide the clamp off the hose and away from the fitting.

What is an everyday use for a hose clamp?

- A common use for hose clamps is securing garden hoses, faucets, sprinklers, or other watering devices.

- In automotive maintenance, hose clamps repair or secure hoses in the cooling system, such as radiator or heater hoses.

- Hose clamps are helpful in plumbing repairs, such as connecting or repairing flexible hoses for faucets, toilets, or washing machines.

- They are used to fasten and organize cables or wires, especially in DIY projects or home workshops.

Do hose clamps loosen over time?

Over time, hose clamps may experience some loosening due to factors like vibrations or thermal expansion. Regular inspection and maintenance are important to ensure the clamps remain properly tightened and to prevent potential leaks or failures.

Why do hose clamps fail?

Hose clamps can fail for various reasons, including corrosion, material fatigue, improper installation, excessive pressure or temperature, and aging. It is crucial to select the appropriate clamp type and regularly inspect and replace them as needed to maintain reliable connections.