Electric Actuators For Modulating Ball Valves

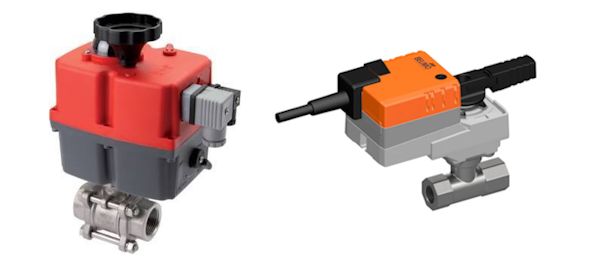

Figure 1: 2-way modulating ball valve with J4C actuator (left) and Belimo ball valve with actuator(right)

An electric actuator in a modulating ball valve system precisely adjusts the valve's position based on control signals, making them essential for applications requiring precise modulation. There are electric actuators for 2-way and 3-way modulating ball valves. This article explores the technical specifications, operational mechanisms, and integration capabilities of these actuators.

View our online selection of electric modulating ball valves!

Types of electric modulating ball valve actuators

Belimo actuators for modulating ball valve

The Belimo electric ball valve actuator (Figure 1 right) can be hand-mounted onto the valve without tools, requiring only vertical movements to ensure proper alignment of the pins with the flange holes. The mounting orientation is adjustable in 180° increments relative to the valve. Additionally, the actuator's rotation angle can be finely tuned in 2.5° increments using a clip, allowing precise setting of the valve's maximum flow rate. It features overload protection, eliminating the need for limit switches by automatically stopping when the end stop is reached. The actuator can be easily removed by clicking it out and can be used to manually rotate the valve spindle. It includes an integrated interface for BACnet MSTP and Modbus RTU, enabling it to receive digital control signals from the control system and provide real-time status updates. BACnet MSTP facilitates HVAC and lighting control, Modbus RTU is known for its reliability in industrial automation, and MP-Bus simplifies HVAC component integration.

J4C actuators

J4C actuators (Figure 1 left) feature robust construction with options for fail-safe (Battery Safety Return, allowing the actuator to fail open or closed during power loss) and modulating (Digital Positioning System) control with analog signals like 4-20 mA or 0-10V. These analog signals allow for fine-tuned adjustments of devices like variable speed drives, dampers, and valves, ensuring optimal environmental conditions and energy efficiency. They provide high torque, fast operation, and are suitable for various aggressive and corrosive media. With an operating torque range of 20-300 Nm, these actuators are suitable for various valve sizes. For maintenance, the ball valves and actuators are sold separately if either need to be replaced.

Read our modulating valve overview article for more information on the design and applications of modulating valves.

How to select a modulating ball valve with actuator

- Configuration: 2-way ball valves are suitable for simple on/off control. A 3-way configuration is used in systems where the flow needs to be redirected between different paths. It is ideal for applications requiring mixing different media or distributing flow to multiple outlets.

- Flow requirements: Determine the flow rate and select a valve with an appropriate Kv value. If the flow rate is less than required, the system may not perform efficiently, leading to inadequate fluid transfer. Conversely, if the flow rate is too high, it can cause excessive pressure drops. Read our Kv calculator for more details on how to size ball valves based on the flow rate.

- Connection size and type: Determine the appropriate size based on the piping system requirements. Ensure compatibility with existing pipe diameters to prevent flow restrictions or leaks. The valve ends are typically flanged or threaded (BSP).

- Voltage: Select the voltage rating that matches the power supply available at the installation site. Standard options include 24V AC/DC, 120V AC, and 230V AC.

-

Housing materials: Ensure the valve materials are compatible with the controlled media. This prevents corrosion and extends the valve's lifespan.Typical housing materials are:

- Brass: Brass is commonly used in general-purpose moderate-temperature applications due to its corrosion resistance. Brass is more cost-effective than stainless steel. However, it is not recommended for chlorides or acidic or alkaline environments.

- Stainless steel: Offers superior corrosion resistance, especially in harsh environments, including those exposed to chemicals, saltwater, and high chloride concentrations. Stainless steel is more durable and suitable for high-pressure and high-temperature applications but is more costly.

-

Seal materials: Typical seal materials are:

- EPDM (Ethylene Propylene Diene Monomer): Excellent resistance to water, steam, and various chemicals, often used for sealing in HVAC and water treatment systems.

- PTFE (Polytetrafluoroethylene): High chemical resistance and durability, suitable for a wide range of industrial applications involving aggressive chemicals. Read our chemical resistance guide for more details on the compatibility of different materials with various media.

- Control signal: An actuator that supports the desired control signal (e.g., 0-10 V, 4-20 mA, BACnet MSTP) is essential for achieving precise control and seamless integration with existing systems.

- Closing pressure: The closing pressure must exceed the expected installation pressure to ensure reliable valve closure.

- Operating time: Select the operating time based on application needs. For example, a valve with a response time of 9 seconds is suitable for applications requiring rapid response, while one with 150 seconds is ideal for systems where gradual valve movement is necessary to prevent water hammer or pressure surges.

- Max temperature: Ensure the valve material can withstand the maximum operating temperature. The maximum temperature limit depends on the housing material; options are available up to 180 𐩑C (356 𐩑F).

- Max actuator torque: Select an actuator with sufficient torque to operate the valve under maximum pressure. Inadequate torque can result in incomplete valve operation or actuator damage.

- Other ball valve features: Consider additional features like manual override, modulating type, and continuous position feedback based on application requirements: