Contact Pressure Gauge

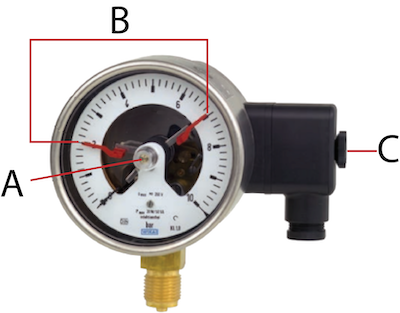

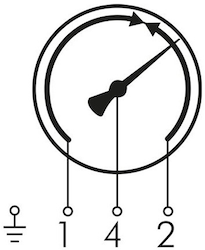

Figure 1: Contact pressure gauge

Contact pressure gauges are pressure gauges with an integrated pressure switch. Depending on the pointer’s location on the dial, the contacts on the switch make or break circuits. Contact pressure gauges monitor limit values; when exceeding or falling below a limit value, a signal is sent out that activates an alarm or cuts off a process to protect people and property. This article explores the definition, types, and working of a contact pressure gauge. Read our article on pressure gauges and pressure switches for a better understanding of the individual components.

Table of contents

- Contact pressure gauge benefits

- Adjusting the set pointers

- Switching functions

- Contact pressure gauge types

- Troubleshooting and maintenance

- Applications

View our online selection of contact pressure gauges!

Contact pressure gauge benefits

- Effective process control: Contact pressure gauges are effective for starting, ending, or controlling processes.

- Real-time monitoring: They can be read on-site to help with real-time process monitoring.

- Easy switch point adjustment: The switch point(s) can easily be set using the adjustment key located at the cable socket. The switch contacts installed in the contact pressure gauge close or open at the set limit values, depending on the designed switching function.

Adjusting the set pointers

Use the adjustment lock and key to adjust the set pointers. Place the adjustment key (Figure 2 labeled C) in the adjustment lock (Figure 2 labeled A), press it in, and set the required set point. The pressure switch/alarm gets activated when any one of the pointers moves outside the set pointer limit (Figure 2 labeled B). The set pointers can be adjusted over the full-scale range. However, considering the switching reliability, accuracy, and the life of mechanical measuring systems, it is advisable to position the set points between 10 and 90% of the total measurement span.

Figure 2: An example of contact pressure gauge parts: Adjustment lock(A), set pointer (B), and removable adjustment key (C).

Switching functions

The switching function in a pressure gauge with a contact switch determines how the pressure switch functions when the set value is reached. The switching function can be normally closed, normally open, or changeover type contact.

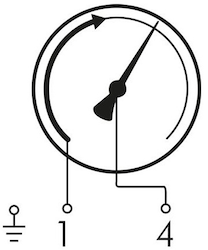

Normally closed

In a normally closed contact, the contact opens when the setpoint value is reached. A normally closed (NC) pressure gauge with switch contacts has two electrical contacts that are normally in contact with each other, allowing current to flow through the circuit. When the pressure reaches the set point, the contacts separate, and the flow of current is interrupted, triggering a switch.

Figure 3: Contact pressure gauge with normally closed single contact showing connection pin numbers 1 and 4 and ground symbol on the extreme left.

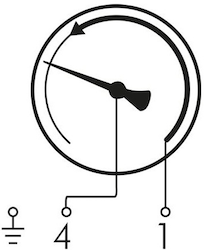

Normally open

In a normally open contact, the contact closes when the setpoint value is reached. It has two electrical contacts that are normally separated, so no current flows through the circuit. When the pressure reaches the set point, the contacts touch each other, allowing current to flow and triggering a switch.

Figure 4: Contact pressure gauge with a normally open single contact.

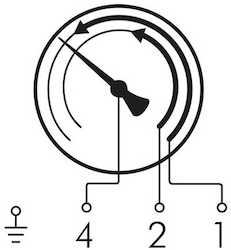

Normally open and normally closed functions can also have double contacts. The double-contact feature allows for redundant and more reliable switching than single-contact switches. For example, in a normally open double contact type, two contacts close when the respective setpoint value is crossed. This switch is often used in applications where a circuit must be interrupted or disconnected when the switch is opened and re-established when the switch is closed (and vice-versa in the normally closed type).

Figure 5: Normally open double contact switching type.

Changeover contact

A changeover contact has a normally closed and normally open contact pair to choose from, depending on the application. Changeover contacts are often used in applications where one circuit must be disconnected and another circuit connected in its place.

Figure 6: Changeover contact.

Contact pressure gauge types

Contact pressure gauges are classified based on the switch contact.

- Magnetic snap-action contact: Magnetic snap-action contacts are switches that turn electric circuits on or off by using the pointer to move a contact arm. They have a special feature that uses a permanent magnet to protect the contacts from sparks that jump across the gap between conductors rather than flowing through the conductors. These switches are durable and can be used in a variety of environments.

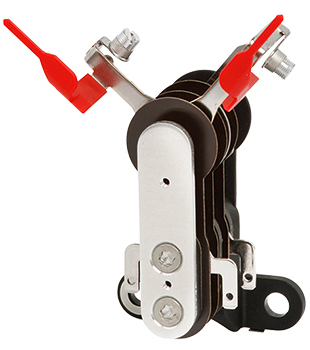

Figure 7: Contact pressure gauge with magnetic snap-action contact.

-

Inductive contact: Pressure gauges with inductive contact are used in two areas:

- Hazardous areas (zone 1 and zone 2)

- Applications involving high switching frequencies

Inductive contacts function without any mechanical contact; therefore, they are highly wear-resistant. Inductive contacts have fail-safe contact operation, no wear and tear, and virtually no effect on the measuring system. Also, no additional control unit is required.

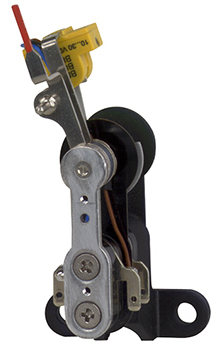

Figure 8: Contact pressure gauge with inductive contact

- Electronic contact: Electric contacts in a pressure gauge can switch on and off small voltages and currents directly, which are used for PLC (programmable logic controllers) and similar applications.

Figure 9: Contact pressure gauge with electronic contact.

- Reed contact: Reed contacts are switches that use a permanent magnet to open or close an electric circuit at a set value. Bistable switches act as reed contacts, which retain their state after a signal changes to the next actuation. They are vibration-resistant due to their design and low weight.

Figure 10: Contact pressure gauge with reed contact.

Troubleshooting and maintenance

Vibrations from the surrounding mechanical instruments, and installation failures can often hinder the optimal functioning of contact pressure gauges. Table 1 illustrates the possible causes and solutions of some of these issues.

Table 1: Troubleshooting contact pressure gauges

| Fault | Causes | Solution |

| Contact chatter (repeated opening and closing) | Vibrations | Mechanically decouple the instrument |

| Switching state remains unchanged despite reaching the switch point/reset point | Defective contacts like a fused contact zone | Replace the instrument |

| Residual current protection device for the circuit is tripped | Insulation failure | Replace instrument |

| No pointer movement despite the change in pressure | Movement blocked | Replace instrument |

The contact is no longer switching in line with the particular specification. |

The electrical connection may be interrupted. | Perform a continuity test on the electrical connection lines using a multimeter |

| Electrical load may not be suitable for the particular switch contact | Maintain the permissible electrical loads for the particular switch contact |

|

| The contact is contaminated |

Maintenance

Contact pressure gauges are generally maintenance-free. However, check the indicator and switching function 1-2 times a year. For this, disconnect the instrument from the process and check with a standard gauge.

Applications

- Control and regulation of industrial processes, such as chemical, petrochemical, and power plants.

- Monitoring of plants and systems and switching of circuits. If there is an overpressure situation, for example, a pressure gauge with an alarm can give a head's up before the equipment gets damaged or a safety risk arises.

- Measuring pressure of gaseous and liquid aggressive media that are not highly viscous or crystallizing, as well as in harsh environments.