Burkert Type 6407 Servo-assisted Piston Valve

Figure 1: Burkert Type 6407 solenoid valve

The Burkert Type 6407 valve is a servo-assisted piston valve. It has a fixed coupling between its pilot valve and piston, enabling it to open without any pressure difference. The valve is particularly suitable for media such as gas, steam, and liquids with a low operating temperature (below 0 𐩑C). The main features of the valve are:

- The valve is servo-assisted and available up to the DN50 orifice.

- The plug and the central guiding tube are welded together to improve their ability to withstand pressure and prevent leaks.

- The valve has a push-over coil system that's vibration-resistant.

- A firmly connected piston system ensures safe opening without any pressure difference.

- Coils with kick and drop are available to reduce power consumption. This involves applying a higher voltage during the initial energization (kick) and then reducing it to a lower level for sustained operation (drop).

- Explosion-proof versions are available.

View our online selection of Burkert 6407 valves!

Is Burkert 6407 servo-assisted valve the right choice for you?

The Burkert 6407 servo-assisted piston valve is reliable and durable; hence, it suits challenging circumstances. This valve might be the right choice for your application if:

- The application demands a leak-free valve structure

- The valve is installed in a high-vibration and potentially explosive atmosphere

- Reducing overall power consumption is a priority

Features and specifications

- Connection size: Available in connection sizes from 3/8 - 2.5 inches (9.5 mm - 63.5 mm)

- Voltage: The voltages available are 24 V/DC, 24 V AC (50/60 Hz), 110 V/50 Hz, 120 V/60 Hz, 230 V/50 Hz, and 240 V/60 Hz. Other voltages can be designed on request.

-

Port connection and communication:

- Electrical connection: Cable plug for cable Ø 7 mm acc. to DIN EN 175301-803 Form A

- Port connection: G ½, G ¾, G 1, G 1 ¼, G 1 ½, G 2, G 2 ½ NPT ½, NPT ¾, NPT 1, NPT 1 ¼, NPT 1 ½, NPT 2

-

Material and orifice sizes

- Seal: PTFE/graphite

- Body: Brass

- Coil: Epoxy

- Orifice: DN 13 - DN 50

- Solenoid coil thermal insulation class: H

- Medium: The valve works with neutral gasses and liquids, such as compressed air, water, hydraulic oil, hot water, and steam.

- Maximum pressure: The valve can handle a maximum pressure of 25 bar (363 psi).

- Approvals and certifications: The valve satisfies IP65 degree of protection when operated in combination with a plug according to DIN EN 175301-803 Form A.

-

Switching time: The valve is designed to operate continuously without overheating, meaning it can run at 100% capacity.

- The Kick and Drop coil, responsible for opening and closing the valve, can handle a maximum of six switching cycles per minute (open and close up to six times per minute).

Table 1: Opening and closing times of Burkert Type 6407 servo-assisted valve

| Orifice size (DN) | Opening time (ms) | Closing time (ms) |

| 13 | 30 | 250 |

| 20 | 30 | 250 |

| 25 | 60 | 700 |

| 32 | 80 | 900 |

| 50 | 500 | 2000 |

Power consumption

Table 2 summarizes the valve's power consumption for AC and DC signals.

- Inrush power: Inrush power is the maximum power needed to activate a valve's solenoid and move it from closed to open.

- Holding power: The lower power required to keep the valve open after activation.

- Cold performance: Cold performance is the valve's power use and behavior at low temperatures, where initial resistance may increase power consumption during startup.

- Warm performance: Warm performance is the valve's power consumption and behavior at normal operating temperatures, indicating its efficiency and power usage during steady-state operation.

Table 2: Power consumption of Burkert Type 6407 servo-assisted valve

Orifice (mm) |

Coil size (mm) |

AC |

DC |

||

| Inrush power (VA) | Holding power (VA) | Cold performance (W) | Warm performance (W) | ||

| 13 | 42 | 140 | 41 | 21 | 16 |

| 13 ATEX | 42 | - | - | 15 | 12 |

| 20 | 42 | 150 | 41 | - | - |

| 25 | 42 | 160 | 41 | - | - |

| 32 | 42 | 170 | 41 | - | - |

| 20 - 25 ATEX | 42 | - | - | - | - |

| 20 - 32 | 65 | - | - | 28 | 21 |

| 50 | 72 | - | - | 39 | 30 |

Circuit functions

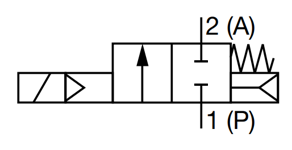

Figure 2: Normally closed, servo-assisted operation of Burkert Type 6407 servo-assisted piston valve

The valve is normally closed, has two ports (inlet and outlet), and is controlled by an external servomechanism. Port 1 (P) is the inlet, and 2 (A) is the outlet. The arrow indicates the flow path that opens when the valve is actuated (Port 1 to 2). The external control mechanism is shown by:

- The triangle symbol on the left side which indicates the valve is piloted or servo-controlled

- The spring symbol on the right side, which shows the valve returns to its closed position when de-energized

Other features

Burkert Type 6407 servo-assisted piston valve can be combined with:

- Type 2518 and Type 2509 cable plugs, Form A, following the DIN EN 175301-803 standard. This allows for a secure electrical connection between the valve and each cable plug.

- Type 1087 timer Form A, according to DIN EN 175301-803, to introduce a delay in valve operation. This setup is ideal for applications requiring precise timing, such as fluid flow control, dosing regulation, or system coordination.