Burkert 3280 & 3285 Control Valves

Figure 1: Burkert 3280 (left) and 3285 (right) control valves

The Burkert type 3280 and 3285 are direct-acting control valves that regulate flow rate. They can include integrated electrical controls for on/off and proportional control. Both types offer open-loop and closed-loop control. Open-loop versions convert an analog input signal (4-20 mA, 0-10V, or a PWM signal) into a proportional valve position. Closed-loop versions have an integrated PID controller for controlling process parameters like temperature or level. The integrated system signals the stepper motor actuator to control the valve’s orifice and fluid flow rate. These valves are suitable for neutral fluid media and come with stainless steel and brass housing.

Some basic features of Burkert 3280 and 3285 include:

- Control of the valve opening and closing by processing the external setpoints.

- LED output indicating the valve states.

- The valve’s position is maintained and restored to the internal electronics even after a power failure.

- The valve has low energy usage as it doesn’t require energy to maintain position.

Read our flow principles of solenoid valves technical article for more information.

View Tameson's selection of Burkert 3280 & 3285 control valves

Table of contents

- Burkert 3280

- Burkert 3285

- Control methods

- Burkert 3280 and 3285 comparison

- Features

- Type 8611 controller

Burkert 3280

Figure 2: Burkert 3280

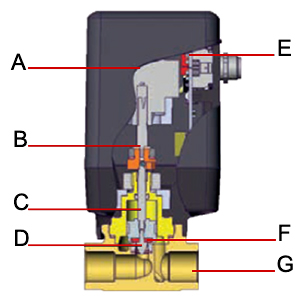

The Burkert 3280 is a 2-way electric globe valve that uses a linear stepper motor actuator (Figure 3 labeled A) to regulate the flow with the aid of an electronic control system (Figure 3 labeled E). The stepper motor is connected to a threaded spindle (Figure 3 labeled B) and valve spindle (Figure 3 labeled C). The spindles are then connected to the control cone (Figure 3 labeled D) and by varying the control’s cone position in relation to the valve seat, the orifice and flow rate can be regulated.

A stepper motor divides a full circular rotation into sections or steps. It is capable of moving one step at a time, which allows for highly accurate positioning. This in turn allows for precision control of the orifice and flow rate. Once in position, it doesn’t require energy to maintain that spot. This makes the Burkert 3280 precise, but still, cost and energy-efficient.

Figure 3: Burkert 3280 components: Linear stepper motor (A), threaded spindle (B), valve spindle (C), control cone (D), control electronics (E), elastomeric seal (F), & body (G)

Burkert 3285

Figure 4: Burkert 3285

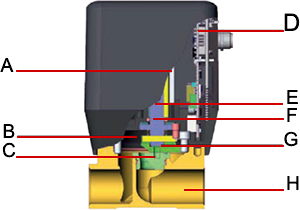

The Burkert 3285 is a 2-way electric disc valve. It uses a stepper motor like the 3280, but in the 3285 the stepper motor is connected to a gearbox (Figure 5 labeled A) and an actuator shaft (Figure 5 labeled F) via a coupling (Figure 5 labeled E). The actuator shaft is ultimately connected to the control disc (Figure 5 labeled G). The control disc and fixed disc (Figure 5 labeled C) have the orifice hole in them. By rotating the control disc, the holes are either lined up (allowing flow-through), partially lined up (proportional control), or blocked (no flow). There is a spring (Figure 5 labeled B) for added force keeping the discs together. Like the 3280, it doesn’t require energy to maintain position, is precise, and cost and energy-efficient.

Figure 5: Stepper motor (A), spring (B), fixed disc (C), control electronics (D), coupling (E), actuator shaft (F), control/ shut-off disc (G), & body (H)

Control methods

A control valve is used when different process parameters like flow, fluid level, temperature, or pressure need to be controlled. The control valve achieves this by controlling the flow passage (orifice) opening size for different parameter setpoints. The Burkert 3280 and 3285 are available in different versions depending on the desired control method of the valve: standard (on/off or proportional control), position controller, or process controller.

Both positioner and process controller versions use analog or digital (fieldbus) signals to control the electronic control system. The basic controls of each version are mentioned below.

Standard device

- On/off control: The valve is switched on/off by processing the external setpoint.

- Proportional control: The valve uses an analog input signal for the set-point. This is either 4-20 mA, 0-10V, or a pulse width modulation (PWM) signal.

Position controller

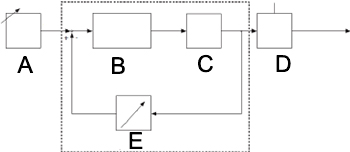

Burkert 3280 and 3285 valves have an integrated position controller to accurately control the valve’s orifice. Figure 6 shows a position controller signal flow diagram. Once the position setpoint (Figure 6 labeled A) is sent to the position controller (Figure 6 labeled B), it controls the actuator (Figure 6 labeled C) to set the orifice size/position of the valve (Figure 6 labeled D). In real-time, a position measuring system (Figure 6 labeled E) compares the valves actual position to the desired position (setpoint). If there is a difference, it will again change the valve’s position to ensure the actual valve position equals the desired position (setpoint). Furthermore, the position controller versions have an output signal to monitor the valve’s actual position.

Figure 6: Position controller signal flow diagram: setpoint value (A), position controller (B), actuator (C), continuous valve (D), & position measuring system (E)

Process controller

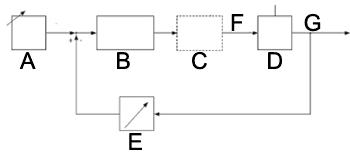

A Burkert 3280 or 3285 valve can also have an integrated process controller. In other words, the valve can be used to control an external process parameter without the use of a separate controller. For example, a temperature, pressure, or level must be controlled. You can send the set-point process value as well as the actual process value to the valve, and the internal PID controller will adjust the valve’s position automatically to achieve the set-point value. Figure 7 shows a process controller signal flow diagram.

Once the process setpoint (Figure 7 labeled A) is sent to the process controller (Figure 7 labeled B) and a position controller (Figure 7 labeled C). The position controller here works the same as in the above section. Once the valve’s position (Figure 7 labeled D) is set and verified, a transmitter (Figure 7 labeled E) measures the process variable (Figure 7 labeled G) and compares it to the process setpoint. If there is a difference, it will again change the valve’s position to ensure the actual process variable equals the desired process setpoint.

Figure 7: Process controller signal flow diagram: process setpoint value (A), process controller (B), position control circuit (C), process (D), transmitter (E), valve opening (F), process variable (G)

Burkert 3280 and 3285 comparison

| Feature | Burkert 3280 | Burkert 3285 |

| Type | 2/2-way electromotive seat valve | 2/2-way electromotive disc valve |

| Flow direction |

Flow direction below the seat is always closed against the medium flow.

|

Flow direction above the seat is always closed with the medium flow.

|

| Orifice Size | 1 to 10 mm | 8 to 25 mm |

| Connection | G or NPT ½, ¼, 3/8 and Cartridge | G or NPT ½, ¾, 1 |

| Speed |

|

|

Features

- Control speed: The control speed for the valve’s actuator can be set. The Burkert 3280 is faster than the Burkert 3285.

- Body and seal material: Both valve types are available in brass and stainless- steel housing. The sealing materials include FKM, NBR, and EPDM. Both housing and seal material are compatible with neutral liquid and gases. For more information on chemical resistance please refer to chemical resistance for housing material, for guidelines how to choose the correct housing material refer to our article on the selection of housing materials.

- Pressure range: Both valve types have a pressure range of 0-6 bar. For high-pressure applications, a special version of Burkert 3280 is available for pressure up to 22 bar.

-

Orifice size: The valves have the following orifice size ranges:

- Burkert 3280: 1 to 10 mm

- Burkert 3285: 8 to 25 mm

-

Port size range: Burkert 3280 and 3285 are available in the following port sizes:

- Burkert 3280: G or NPT ½, ¼, ⅜

- Burkert 3285: G or NPT ½, ¾, 1

- IP rating: Based on the degree of protection, Burkert 3280 and 3285 has IP 54 and IP 50 rating, respectively.

- Approval: Versions are available with FDA approval for use with food-grade applications.

Type 8611 controller

The Burkert proportional controller type 8611 can be used together with the Burkert 3280 or Burkert 3285 valves for optimal process control. The Burkert 8611 contains a PI controller so that external process parameters such as a flow rate or temperature can be controlled.

Figure 8: Burkert 8611 proportional controller