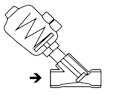

Burkert Type 2000

Figure 1: Burkert Type 2000 pneumatic angle seat valve

The Burkert 2000 series includes 2-way manual and pneumatic angle seat valves. The Burkert CLASSIC actuator drives the pneumatic valve. They are known for their long service life, high flow rate, robust actuators, and durable housing. This article explores the main features of these valves and the actuator.

Table of contents

- Pneumatic angle seat valve

- The CLASSIC actuator

- Manual angle seat valve

- Manual vs pneumatic control

- Applications

View our online selection of Burkert 2000 angle seat valve actuators!

Pneumatic angle seat valve

A single-acting or double-acting piston actuator controls the angle seat valve. The main features of the valve are the following:

- The valve has an almost straight path favoring a high flow rate

- Robust and maintenance-free design

- The valve can be retrofitted with various accessories for stroke limitation, position indication, or manual override

- Gunmetal or stainless steel housing with clamped, threaded, or welded connection

- Suitable for slightly aggressive or contaminated fluids

- The valve body has a self-adjusting packing gland for added tightness

The valve can be controlled through the use of a pilot valve or central automation with a valve island. The valve can be fitted with accessories like electrical position feedback, manual override, or stroke limitation.

Technical data

| Description | Details |

| Port connections | Clamp, threaded, welded |

| Housing material | Gunmetal, stainless steel |

| Port connection size | DN 10- 80, NPS ⅜ - 3 |

| Safety setting (in the case of power failure) | Normally closed (control function A), normally open (control function B) |

| Media | Neutral gasses, alcohol, water, fuel, oils, salt solution, hydraulic mediums, alkali solutions, steam, organic solvents, optional variants for oxygen and fuel gas |

| Medium temperature | -40 to 230 °C |

| Viscosity | Maximum 600 mm2/s |

| Approvals and certificates | ATEX / IECex certified and conforms to Food contact 1935/2004 (EG), FDA Drinking water Pressure Equipment Directive Gas Appliances Regulation Machinery Directive |

| Ambient environment temperature | -40 to 140 𐩑C |

| Degree of protection | IP 67 |

Product versions

The pneumatic angle seat valve comes in three different versions depending on the body material:

- Gunmetal body with PA actuator

- Stainless steel body with PA actuator

- Stainless steel body with PPS actuator

Circuit functions

Table 1 lists the common circuit functions of the Burkert Type 2000 pneumatic valve. Depending on the media, the flow direction can be above or below the seat. Flow above the valve seat can cause a risk of damage due to bursting pipes and bursting equipment. 'Flow above the seat' refers to a situation where the flow of the liquid is more than the valve's capacity to control or manage. This could be due to high pressure or high volume of the liquid. This results in water hammer that can burst the pipes in liquid mediums. So, it is advisable not to use the angle seat valve with flow above the seat for liquid media.

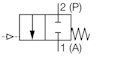

Circuit function A (CF:A)

- Flow direction below seat

- Normally closed by spring force

Figure 2: Circuit Function A

Figure 3: Valve sketch

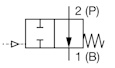

Circuit function B (CF:B)

- Flow direction below seat

- Normally open by spring force

Figure 4: Circuit Function B

Figure 5: Valve sketch

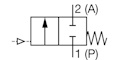

Circuit function C (CF:C)

- Flow direction above seat

- Normally closed by spring force

Figure 6: Circuit Function C

Figure 7: Valve sketch

The CLASSIC actuator

The Burkert CLASSIC actuator for pneumatic valves is made from polyamide (PA) for standard applications and polyphenyl sulfone (PPS) for high temperatures or enhanced chemical resistance. It uses less energy through clever volume fillers that do not impede the stroke. The actuator is designed to last longer, with each part molded in-house to Burkert's high-quality standards and assembled within robot cells. The actuator is also designed to mount a Burkert 8697 feedback and control unit directly.

Figure 8: Burkert type 2000 CLASSIC actuator

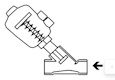

Manual angle seat valve

Figure 8: Burkert Type 2000 manual angle seat valve

The Bürkert Type 2000 manually-operated 2-way angle-seat valve is designed for on/off applications. It can be actuated manually with a PPS rotary handle. The valve can handle fluids with viscosities up to 600mm2/s. Some of the key features of this valve are:

- The valve can be operated above or below the seat in any flow direction.

- It has a housing made of durable materials like brass or stainless steel with PTFE sealing; therefore, it can withstand harsh operating conditions.

- The maximum pressure depends on the version but is limited to 6 bar.

- The valve is available with G or NPT threads and welded ends.

- It is ATEX and IECEx certified for zones 21/1 and 22/2.

- A compact position feedback and control unit can be easily mounted on the actuator.

- Flow below-seat versions are suited for liquids, steam, and gasses.

However, the valve has no control cone, so the user can't regulate its flow rate. Consider the Burkert Type 2712 pneumatic globe valve with a control cone to regulate the flow rate manually.

Manual vs pneumatic control

The choice between manual and pneumatic control would depend on factors like:

- Frequency of operation

- Need for automation

- Availability of a power source

- The installation environment

- Cost

For example, manual valves are ideal for systems requiring fewer adjustments and precise control. They are cost-effective and easy to install but unsuitable for quick or frequent adjustments. Pneumatic valves are suitable for automated systems needing frequent or high-speed operations. They allow for remote control and efficient operation but require a compressed air source and can be more complex to install.

Applications

The Type 2000 is well-suited for a range of applications, including:

- Steam processes such as food sterilization and cleaning in place (CIP)

- Water and wastewater treatment

- Beverage and food bottling

- Pharmaceutical and medical industries

- Textile machines, including clothing manufacturing

- Cleaning and washing industries

Also, there are other pneumatically actuated angle seat valves from Burkert (like Bukert 2060)that are suitable for corrosive media and harsh environments.