Bearing Puller Types

Figure 1: An external bearing puller removes a bearing from a shaft.

Different bearing puller types are available to handle various bearing pulling tasks. Some bearings are easily accessible, whereas others are difficult to reach. After determining a few factors, selecting the correct bearing puller for the job is not difficult. This article aims to help readers understand how to choose between the types to complete the work faster. To learn more about how these pullers function, read our article on bearing pullers.

View our online selection of bearing pullers!

What type of bearing puller to use

The bearing type (e.g., ball bearing or roller bearing) does not impact which bearing puller to use. The important factors are access to the back of the bearing, bearing size, removal difficulty, and job size.

- Access to external diameter: If the bearing's back is accessible, it's best to use an external bearing puller because they are the most efficient type. An internal bearing puller is necessary if the bearing is inside a housing or other recess.

- Bearing size: The size of the bearing determines the size requirement of the bearing's gripping mechanism. However, for very large bearings, hydraulic bearing pullers are typically necessary.

- Removal difficulty: Hydraulic bearing pullers make the job easiest to complete for bearings that are especially tight or rusted on.

- Job size: For small jobs, manual bearing pullers are acceptable. However, use a hydraulic puller for larger jobs so the job can be completed efficiently.

External bearing puller

When there is access to the bearing's outer diameter, use an external bearing puller (jaw puller) to remove the bearing. External bearing pullers have two or three legs, each with a hook on the end for gripping the bearing.

- Two-legged vs three-legged: Two-legged pullers are more compact and suitable for relatively easy-to-remove bearings. Three-legged pullers provide a stronger grip and force distribution during removal. While these are better suited for more stubborn bearings, they are typically larger.

Actuation

External bearing pullers have manual or hydraulic actuation. Manual action is suitable for smaller jobs that require only a few bearings to be pulled. For efficiency, use hydraulic bearing pullers for larger jobs or jobs with especially difficult-to-remove bearings.

Figure 2: External bearing pullers can have manual (left) or hydraulic (right) actuation.

Reach and spread

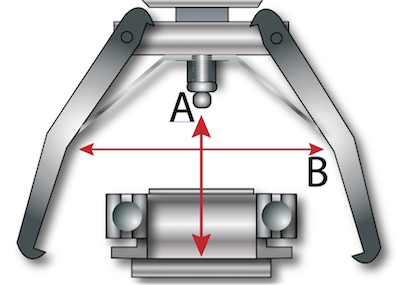

External pullers have maximum reach and spread. The reach (Figure 3 labeled A) is the distance between the puller's center bolt (force screw) and the back of the bearing where the legs grip. The spread (Figure 3 labeled B) is the distance the legs can open. Before choosing an external bearing puller, ensure that its reach and spread are enough to work with the bearings that need to be pulled.

Figure 3: An external bearing puller's reach (A) and spread (B).

Internal bearing puller

An internal bearing puller, also known as a blind bearing puller, extracts bearings from blind holes. A blind hole means no access to the back of the bearing. This puller has collets that insert into the bearing's internal raceway, which is accessible even if the bearing is fitting onto a shaft. Then, an expanding sleeve inserts between the collets to expand them so they can securely grip the inner raceway. Finally, the operator repeatedly and quickly moves the slide hammer away from the bearing to apply the force necessary to remove it.

Bearing separator

A bearing separator or splitter is another tool available when an external bearing puller won't work. In this case, there is limited space between the back of the bearing and another piece of the machinery. Bearing separators are flat plates with tapered edges. The tapered edges can fit into the limited space, and through further tightening and an attachable puller, remove the bearing. Separators are not efficient tools, however, and should be used when an internal bearing puller is unavailable.

Reversible bearing puller

Reversible bearing pullers are small bearing pullers with legs that can be reversed to either grip externally or internally. This type of puller is operated manually but is still valuable in applications with bearings placed on shafts and blind holes.

FAQs

How many types of bearing pullers are available?

There are several types of bearing pullers, including external, internal, reversible, and hydraulic pullers. Bearing separators/splitters are also available.

What is a 3-jaw puller used for?

A three-jaw bearing puller is used to externally or internally provide greater force distribution when removing a bearing from a machine.

What is a blind bearing puller?

A blind bearing puller is used to pull bearings that cannot be removed with an external bearing puller. Its mechanisms fit into the bearing's inner race.