How To Bend a Copper Pipe

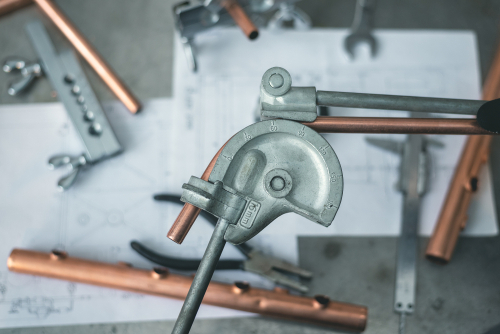

Figure 1: A ratchet bender bending copper pipe.

Copper pipes are popular in domestic water distribution, air conditioning and refrigeration, fire sprinklers, and crafts. These copper pipes are bent using specialized pipe benders or everyday household objects, such as springs or sand. Each technique varies with respect to ease of use and smoothness of the finish after bending. This article explores and compares the methods used for bending a copper pipe.

Table of contents

- Copper pipe applications

- How to bend copper pipe using a pipe bender

- How to bend copper pipe without a pipe bender

- Tips for bending copper pipe

- FAQs

Check out our selection of pipe and tube processing tools!

Copper pipe applications

Read our pipe bending material guide to learn about bending other types of pipes.

Copper pipes are used frequently at home as water supply pipes. These pipes are also used as crafting materials owing to their decorative properties. Copper is soft and easy to work with, but the material is not soft enough to bend perfectly on its own. Bending copper pipes without specialized tools can result in pipe collapse, meaning the pipe may form uneven edges instead of a smooth curve at the intended bend point. This can impair an artistic look in crafting and impede water flow in plumbing.

Figure 2: Copper pipes for carrying water.

How to bend copper pipe using a pipe bender

A manual pipe bender is a small, inexpensive tool that bends various sizes of copper and other soft metals to a set radius. Dual pipe benders are a common example of manual pipe benders. As seen in Figure 3, the copper pipe can be inserted down the middle of the dual pipe bender. The marked gauge indicates the bend angle from zero to 90 degrees. The top portion of the pipe bender (called a shoe), travels along the bend, ensuring a smooth and perfect curve.

Figure 3: A dual pipe bender bending a copper pipe.

Advantages

- Accurate and smooth bending

- Easy operation

- No need to heat pipes

Disadvantages

- A different bender is required for each pipe size

- Expensive

How to bend copper pipe without a pipe bender

Use a spring

Using a bending spring is the easiest way to bend copper pipes without a pipe bender. A bending spring is a strong and flexible spring that is inserted into (or on the surface) of a copper pipe. The spring supports the pipe walls while bending it manually. There are two types of bending springs: internal and external.

- Internal bending springs: These springs fit inside copper pipe that has 12 - 22 mm outside diameter. They prevent the pipe’s wall from collapsing during the bend.

- External bending springs: These springs fit over a copper pipe that has 6 - 10 mm outside diameter. They prevent the pipe’s wall from spreading outwards during the bend.

Tube springs are capable of forming 180° bends. Perform the following steps to bend a copper pipe with a tube spring:

- Clean off/deburr any rough edges at the copper pipe’s ends resulting from cutting the pipe.

- Use a permanent marker to highlight a point on the copper tube where the bend will be made. Ensure to mark the point at the outermost point of the bend radius. The bend radius is the minimum radius that a pipe can be bent, without damaging it.

- Choose a correct-sized spring for the pipe and put the spring in the pipe or around the pipe, depending on the pipe’s diameter..

- If the spring is longer than the pipe, it can be easily retrieved after bending.

- If the spring is shorter, attach a wire to the end of the spring.

- Pad the copper pipe with a soft cloth.

- Bend the copper pipe over the knee. Move the pipe back and forth on either side of the knee to create a smooth bend.

- Remove the spring from the pipe. The spring can get trapped on the bend. If the spring is difficult to remove, twist it clockwise and try again.

- A second method is to bend the pipe past the desired angle and then unbend it to the desired angle.

Bending a copper pipe using springs is less expensive than using a pipe bender. Also, springs are easy to store and transport. But differently sized springs are required for each pipe size.

Figure 4: Internal bending spring (up) and a external bending spring (down).

Use sand or salt

Dense materials like fine sand or salt produce an effect like pipe-bending springs and distribute force along the entire length of the curve. Perform the following steps to bend a copper pipe using fine sand or salt:

- Straighten out the copper pipe or tube. Make the pipe straight enough for the sand or salt to move fully through it.

- Use duct tape to close one end of the copper pipe.

- Use a funnel to fill the copper pipe with sand or salt.

- Tape the other end of the copper pipe.

- Bend the pipe until the desired curve is attained.

- Remove the tape and allow the sand or salt to flow out of the pipe.

Bending a copper pipe with sand or salt doesn’t require additional costs, but the process is time-consuming.

Use a blow torch

Copper pipes can be heated and bent using a small butane torch or oxy-acetylene torch. A butane torch takes more time to heat the pipe to the required temperature for bending. Oxy-acetylene torch heats the copper pipe red hot and aids fast bending of the pipe, and this is a better choice when there are multiple copper pipes to bend.

After determining where to bend the pipe and marking the location on the pipe:

- Fasten the pipe to a table to keep it steady. If the table is wooden, keep the part to be heated away from the table.

- Heat the pipe until it is red hot.

- Let the pipe cool until it can be touched.

- Hold the pipe and bend it to the desired bend.

- For additional bends, repeat steps 2 - 4.

Putting sand in the copper pipe after it cools and before bending it will help prevent kinks.

Figure 5: Blow torch

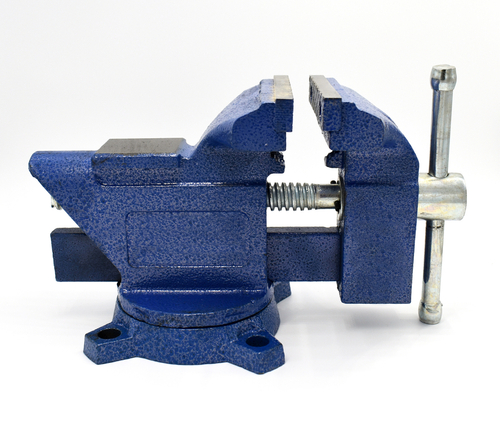

Use a vice

Perform the following steps to bend a copper pipe using a vice:

- Heat the copper pipe red hot along its length.

- Put the heated pipe quickly into the vice and close the vice until it just touches the pipe.

- Pull the pipe up at both ends to achieve the correct angle while it is still hot. The vice supports the pipe ends to avoid them from collapsing.

This method of bending a copper pipe is easy as only a vice is needed. However, the technique is tricky; hence, the user needs to be skilled and quick.

Figure 6: Vice

Tips for bending copper pipe

- Pipe support: Support the copper pipe along the entire length to get a consistent shape. The support can either be internal or external to the pipe.

- Bend slowly: A properly supported copper pipe can crease if bent quickly. Also, ripples may develop on the inside portion of the pipe. So, always bend the copper pipe slowly.

- Shape the bend: Use curve-shaping elements like buckets, metal cans, or large pipes to bend the pipe.

FAQs

How do you bend a copper pipe without a bender?

Use sand or a bending spring to distribute the force along the length of the curve, and then bend the copper pipe.

Do you need to heat copper to bend?

Not necessarily. However, if heating a pipe, heat the copper pipe with an acetylene torch to make it soft. The pipe can then be bent without breaking it.