How Does a Bimetallic Thermometer Work?

Figure 1: Bimetallic thermometers

A bimetallic thermometer is a temperature measurement device. It converts the media’s temperature into mechanical displacement using a bimetallic strip. The bimetallic strip consists of two different metals having different coefficients of thermal expansion. Bimetallic thermometers are a simple, durable, and cost-efficient way of temperature measurement. Bimetallic thermometers are also sometimes referred to as bimetal thermometers.

Table of Contents

- Construction and design

- Advantages and disadvantages of bimetallic thermometers

- Types of bimetallic thermometer

- Selection criteria

- Bimetallic thermometer calibration

- Applications

View our bimetallic thermometer selection here!

Construction and design

A bimetallic thermometer works by using two basic properties of metal:

- The thermal expansion property of the metal

- The coefficient of thermal expansion of different metals is different for the same temperature.

The main component of the bimetallic thermometer is the bimetallic strip. The bimetallic strip consists of two thin strips of different metals, each having different coefficients of thermal expansion. Thermal expansion is the property of a metal to change its shape or volume with a change in temperature. The metal strips are connected along their length by fusing them together or riveting. The strips are fixed at one end and free to move on the other end.

The two metals typically used are steel and copper, but steel and brass can also be used. Since their thermal expansion is different, the length of these metals changes at different rates for the same temperature. Due to this property, when the temperature changes, the metal strip at one side expands and the other does not, which creates a bending effect. This can be seen in Figure 2.

When the temperature rises, the strip will turn in the direction of metal with the lower temperature coefficient. When the temperature decreases, the strip bends in the direction of metal having a higher temperature coefficient. The deflection of the strip indicates the temperature variation. This bending motion is connected to the dial on the thermometer, outputting the media’s temperature. Calibration is an important step to ensure the correct temperature reading.

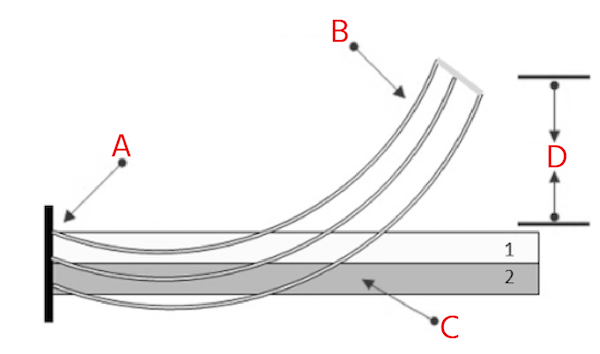

Figure 2: Bimetallic strip: fixed end (A), free end (B), bimetallic strip (C), and deflection(D)

Advantages and disadvantages of bimetallic thermometers

The advantages of bimetallic thermometers include:

- Simple and robust design

- Less expensive than other thermometers

- They are fully mechanical and do not require any power source to operate.

- Easy installation and maintenance

- Nearly linear response to temperature change

- Suitable for wide temperature ranges

Some disadvantages of bimetallic thermometers are:

- They are not advised to use for very high temperatures.

- They may require frequent calibration.

- May not give an accurate reading for low temperature.

- Calibration is disturbed if roughly handled

Types of bimetallic thermometer

There are two types of bimetallic thermometers, helix strip bimetallic thermometer and spiral strip bimetallic thermometer. The helix and spiral strips are used to keep the thermometer size within a manageable limit.

Helix strip bimetallic thermometer

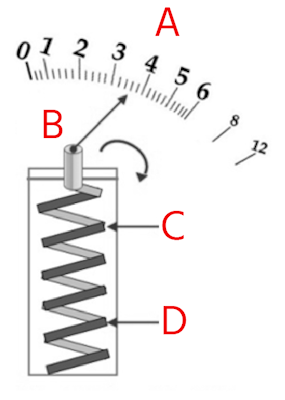

As the name suggests, a helix-shaped bimetallic strip is used to measure the temperature in this type of thermometer. The pointer is connected through the shaft at the free end of the strip. The strip is wound helically inside the stem, as illustrated in Figure 3. As the temperature increases, the helical strip senses the temperature change. The strip metal with a higher coefficient of thermal expansion expands and winds up along the stem, rotating the shaft. This rotation causes the pointer to move its position in the dial which indicates the media’s temperature. As the temperature decreases, the metal with a lower coefficient of thermal expansion shrinks and rotates the shaft. The pointer then reads the lower temperature in the dial.

These are mostly used for industrial applications, as they can be placed inside a thermowell which provides operation in high temperature and pressure environments.

Figure 3: Helix strip bimetallic thermometer: temperature scale (A), pointer (B), bimetallic helix (C), bulb (D)

Spiral strip bimetallic thermometer

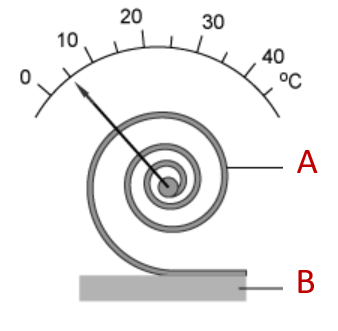

A spiral-shaped strip is used to measure the temperature in a bimetallic spiral strip thermometer, as seen in Figure 4. As the temperature rises, the two metal strips expand differently. This creates a bending effect and the strip coils in such a way that the metal with a higher thermal coefficient forms the outer side of the arc. As the temperature decreases, the metal with a lower thermal coefficient forms the inner layer of the arc. The pointer and dial attached to the spiral read this deformation which indicates the media’s temperature.

These are mostly used for thermostats or measuring the ambient temperature, as they’re sensitive to lower temperature variation.

Figure 4: Spiral strip bimetallic thermometer: bimetallic strip (A), fixed end (B)

Selection criteria

The following selection criteria should be considered when selecting the bimetallic thermometer for your application:

- Temperature range: The bimetallic thermometer should be within the upper and lower limit temperatures. Due to extreme temperatures, metals may reach their expansion limits and not rebound causing the thermometer to be permanently damaged.

- Stem: The length and diameter of the stem for the bimetallic stemmed thermometer should be determined as required by the application. This may require determining the immersion length or depth of the tank where the thermometer will be used.

- Thermowells: A thermowell is a cylindrical tube fitting which protects the temperature sensors installed in industrial applications. It acts as a barrier to protect the expensive thermometer from any potential damage from the process fluid. Thermowells must be used where the stem may be exposed to extreme temperature, pressure, high velocity, or fluid of corrosive nature. With a thermowell installed, thermometers can be easily removed and replaced without stopping the process. As the thermowell protects the thermometer, it lasts longer reducing maintenance and replacement costs.

- Type of thermometer: The bimetallic thermometer can have a helix strip or spiral strip. The helix strip thermometer is preferred for industrial applications such as refineries, oil burners, etc. The bimetallic strips are wound helically inside the stem and they can be supported by thermowells to work with extreme temperature and pressure. Spiral strip thermometers are used in thermostats for their sensitivity to low-temperature variations.

Bimetallic thermometer calibration

The most accurate method for calibrating the bimetallic thermometer is the ice-point method. To calibrate a bimetallic thermometer using this method, fill a glass completely with ice, add cold water, and let sit for 4 to 5 minutes. Then, insert the stem of the thermometer into the ice water. Make sure the stem is not touching the bottom or sides of the glass. Let it sit until the dial stops moving. If the thermometer is accurate, it should measure 0°C or 32°F. If not, rotate the nut located under the dial so that it reads 0°C. Check on regular intervals to ensure accuracy. A weekly or monthly thermometer calibration process should be put in place depending on your application requirements.

Applications

The bimetallic thermometers are used for residential as well as commercial purposes. The most common bimetallic thermometer applications are:

- Air conditioners

- Thermostats

- Control devices

- Heater

- Ovens

- Hotwires

- Refineries

- Oil burners

FAQ

Does the whole tube have to be immersed in the medium, or is the tip enough?

The entire tube must be immersed in the medium. The tube contains a bimetal coil that is deformed by temperature. For an accurate measurement, it must come completely in contact with the medium.