Soldering Iron Tip Care Guide

Figure 1: Soldering iron tip

A soldering iron is the hand tool used to join two or more metals together by providing heat. A connection is established between two metals with the addition of a filler metal called solder. The proper care and use of the soldering iron tip increases soldering production and decreases solder joint failure. The soldering iron has to be cleaned and maintained in a way that increases its longevity and maximizes its soldering capabilities. A complete guide to taking care of a soldering iron tip is discussed below.

Table of contents

- Why a soldering tip needs cleaning

- How to take care of a soldering iron tip

- Precautions to be taken while soldering

- FAQs

View our online selection of soldering equipment!

Why a soldering tip needs cleaning

During soldering, the soldering tip comes in contact with different substances and collects residue over time that needs to be cleaned as seen in Figure 2. The collection of residue is caused by the following:

- Rusting of the soldering iron tip causes surface residue that obstructs the proper adhesion of the solder to the tip.

- The tip of a soldering iron gets oxidized rapidly acting as an insulator prohibiting proper heat transfer to melt the solder while working on a project.

- Using a poor quality solder that has impurities may result in a solder build-up on the soldering iron tip which hampers efficient heat transfer while soldering.

- Using excessive heat on a soldering iron tip can result in oxidation and reduce the lifespan of the tip.

- The features of the ironing tip aren’t as easily distinguishable if a residue is collected on it. For example, a soldering iron with a conical tip may get flattened over time due to the collection of residues due to which their properties like being used for general purpose applications are not met properly.

Figure 2: A soldering iron tip with residue on its surface

How to take care of a soldering iron tip

Soldering tips wear out with time and need to be replaced. But taking a few steps to take care of the tips can extend their life and improve the quality of soldering work. The following practices may be adopted to ensure better soldering action and improved longevity of the iron tips:

Tinning the solder tips

- Tinning is the process of covering the tip with a thin amount of solder to prevent oxidation of the soldering iron tip.

- Tinning should be done ideally at the beginning and end of the soldering process and also regularly during the process.

- Start by thoroughly cleaning the tip, and then coat enough solder to make the tip shiny.

- Flux is a substance that removes oxidation. Flux helps to erase oxidation on the parts being soldered and enables the solder flow. Certain solder has flux at its core, but it can also be used separately in a paste form.

Use high-quality solder

- Never trade-off the quality of solder for money because poor quality solder will contain impurities which will reduce the efficiency of heat transfer between the tip and the solder.

- It is advisable to do proper research and choose an optimum solder for the project from well-known brands.

Keep the tips clean

- Clean the tips thoroughly and regularly to ensure the best results while soldering and improve the device’s longevity.

- Remove grease from the tip before starting the soldering process by cleaning it with a cloth dipped in denatured alcohol.

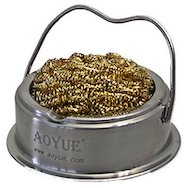

- Use stainless steel wool to keep the tips shiny and free from oxidized matter during the soldering process.

- The traditional way of cleaning the tip is by using a damp sponge. But, it produces constant temperature changes, which are not healthy for the soldering iron tip.

- Use a soldering iron cleaning tip sponge to clean the tip. The sponge need not be wet, hence doesn’t cause temperature fluctuations at the hot iron tip. This should be part of your soldering station.

Figure 3: Soldering tip cleaning sponge

Use optimal temperature

It is important to set the temperature of the soldering equipment to the lowest possible value that still allows for proper and efficient soldering. Using too high of a temperature for soldering can make the process quicker in the short term, but over time it can damage the components on the board and reduce the tip’s life span. Consider purchasing a soldering iron with a built-in temperature sensor to maintain the correct temperature.

Reactivate the tips

If the tip appears dark and oxidized, it should be reactivated. A reactivation paste can be applied to the tip to break down and remove the oxide layer on the tip surface. After placing the tip in the paste, gently move it around until it appears shiny, and perform tinning afterward.

Store the solder tips with care

Soldering tips should be stored in optimal places. Improper storage may cause unnecessary and accidental damage to soldering tips that can be avoided with proper storage.

Precautions to be taken while soldering

While soldering, it is important to take the following precautions:

- Solder and solder flux may splatter; hence it is advisable to wear safety goggles while soldering.

- Use a fan to blow away fumes produced when the solder melts.

- Ensure that capacitors are completely discharged, and switch off the power supply of the electric board under operation.

- Don’t heat the soldering iron for more than a few seconds; else it may damage the components due to overheating.

- Never apply excess pressure on the soldering tip to ensure that the tip or the board doesn’t get damaged.

FAQs

How can you prevent a soldering iron tip from corrosion?

Perform tinning to prevent a soldering iron tip from corrosion. Clean the tip and coat the tip with a thin layer of solder.

Why is my soldering iron not getting hot enough?

Check for any breaks in the electrical circuit resulting from a faulty connection in the iron.

Why is my solder not sticking to the iron?

The copper wires used may not be clean enough or hot enough and can be mechanically cleaned.