Fuel, Oil, Gas, And Propane Solenoid Valves

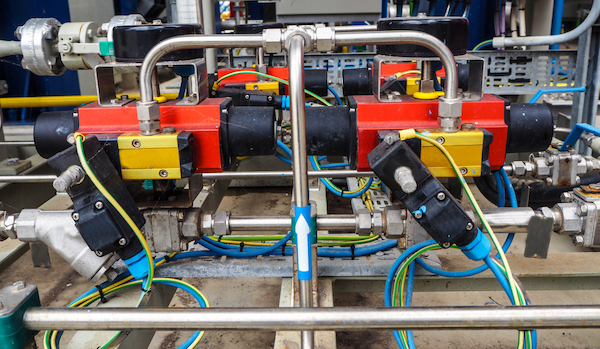

Figure 1: Solenoid valve for fuel, oil, gas, and propane applications

Solenoid valves used in oil and gas applications are designed to control the direction of fuel gas, liquid propane, and other grades of fuel oil used in combustion applications like industrial boilers, furnaces, incinerators, and ovens. The valve can shut off the gas or oil supply remotely. Typical solenoid valves for gas, fuel, oil, and propane are available in 2-way normally closed, 2-way normally open, 3 way normally closed, 3 way normally open, and 3-way universal function with direct-acting, servo pilot pressure-assisted, or assisted pilot operation. This article discusses the features of solenoid valves making them worthy of being installed in harsh environments, how to select the valve materials, and other selection criteria. Read our solenoid valve basics article for more information on the working and types of solenoid valves.

View our online selection of solenoid valves!

Solenoid valves for fuel, oil, gas, and propane

A solenoid valve is an electromechanical valve used to control the flow of liquids or gases. These valves have very low reaction times due to the presence of controller circuits, and they are commonly used in fuel injectors. Autogas systems use different categories of valves like shut-off and filter-lock valves that may be operated on electricity or vacuum. Bi-fuel systems typically use shut-off valves.

Benefits of solenoid shut-off valves

Historically, pneumatically controlled shut-off valves were used in process heating system burners. But these valve units require pilot valves for control and require additional equipment and piping, adding to the overall expense. Also, pneumatic valves eject methane gas into the atmosphere during operation.

The relatively high power consumption and the inability to cope with a broad range of working pressures made these valves ill-suited for remote pipeline or tank locations. Also, most installed systems using older valve technologies failed to comply with current safety regulations.

The following are the benefits of solenoid valve for fuel applications in a process heating system:

- Longer service life and higher reliability in harsh environments.

- Less supporting equipment and lower maintenance levels resulting in reduced lifecycle costs.

- Less energy consumption and increased equipment uptime.

- Environment-friendly by not venting gas into the atmosphere.

- Compliance with current safety regulations.

Figure 2: On-off solenoid valve for regulating fuel flow in a power plant

Fuel, oil, gas, and propane

Fuel is a substance that is burned to produce heat energy. Fuel can be classified into solid, liquid, and gaseous types. Typical examples of fuels are:

- Solid: coal, wood

- Liquid: petrol, diesel, kerosene

- Gas: Natural gas, hydrogen, biogas

Oil is a fuel found on the earth’s surface from which petroleum products like diesel, kerosene (or paraffin), and many other chemical substances can be extracted. These oils are used as fuels in vehicles, heaters, and other equipment. Propane is an environment-friendly by-product of domestic natural gas processing or crude oil refinement. It is also called liquified petroleum gas (LPG), where the gas is usually compressed and stored as a liquid. Hence, fuel is a broad group that includes several oils, solids, and gases suitable for combustion.

Selection of materials

It is essential to select suitable materials for the media used in the application. Please refer to our solenoid valve housing material, seal material, and overall chemical compatibility chart for further information.

Fuel gas

For maximum life and performance of the valve, choose materials like brass, aluminum, steel, or cast iron for the body and nitrile rubber for the sealing.

Fuel oil

In a fuel oil system, it is necessary to consider the particular fluid temperature as viscosity changes with temperature. Also, the maximum and minimum pressure of fluid operation and the required Kv value should be considered. A solenoid valve with a brass body and FKM sealing is an acceptable choice for the maximum working efficiency of the valve. FKM provides a balance of material compatibility and long life.

Natural gas and propane

Natural gas and propane are compatible with brass, aluminum, cast iron, or steel for the body, and nitrile rubber for the seal material of the valve. The valve works on a wide range of pressure for the medium from very low to very high (typically 30 psi or higher). If the application sees extreme temperatures of valve operation, make sure to rate the valve accordingly. Very low ambient temperatures (like 400C) require specialized elastomers for leak-free sealing. High ambient temperatures need Class H coil insulation for proper operation.

Selection criteria

Consider the following factors to make the right technical and commercial choice:

- Selection of materials: Selecting materials for a valve’s particular application is the most prominent selection criterion.

- Explosion-proof: As the fuel media used in the solenoid valve is highly combustible, sufficient care must be taken to prevent any spark from originating within the coil or housing. The valve’s coil or enclosure must be explicitly specified to suppress any explosion originating from the valve. There are several standards for classifying devices for a hazardous environment like NEMA (National Electrical Equipment Manufacturers Association (USA), ATEX (Atmosphères Explosibles (EU), and IEC Ex (International Electrotechnical Commission Explosive (global)). While purchasing a valve for working with explosive fuels, make sure to check the marks of one of these standards on the valve.

- The number of ways: A solenoid valve is usually designated as 2/2 valve or 3/2 valve. A valve designated as a/b has ‘a’ number of ports and ‘b’ number of port states. For example, a 2/2 valve has two ports (inlet and outlet port) and two positions (open and closed). A 3/2 way valve has three ports and two positions.

- Switching function: Based on the switching function, a solenoid valve can be normally open (NO) or normally closed (NC). A normally closed solenoid valve is closed when de-energized, not allowing the media cannot flow through it. A normally open solenoid valve is open when de-energized allowing the media can flow through it. A normally open solenoid valve is ideal for applications that require the valve to be open for long periods of time as this is then more energy efficient. Read our article on normally open and normally closed solenoid valves for more details and their working.

- Connection size: The solenoid valves come with a wide pressure rating, flow rates, and orifice sizes. The orifice size determines the flow rate of the fluid; therefore, select the size accordingly by checking the valve manufacturer specifications. The Kv value measures the flow rate through a valve for a given medium and pressure drop. If the medium characteristics, the pressure drop, and the desired flow rate are known, the minimal required Kv-value for the valve can be calculated. Different formulae apply for fluids and gases. Use our Kv calculator to calculate the Kv value of the concerned fluid to select an appropriate valve.

-

Type of connection: The valve can be connected to inlet and outlet pipes through several ways like threaded, flanged, and welded joints.

- Threaded: These piping connections are one of the oldest mechanisms of connecting pipe systems. Thread fittings are classified into two: male and female. Male threads are found on the outside surface of pipes or fittings, while female threads are located inside.

- Flanged: A flanged connection is a combination of bolts, gaskets, and pipe flanges, and the link is not permanent.

- Welded: The pipe end is fused to the valve orifice in a welded connection by applying heat.

- Working pressure and response time: The maximum working pressure of the inlet and outlet media flow to the valve should be considered, and choose a valve that best fits the range. Pilot-operated solenoid valves are used to control the flow of petrol and other flammable fuels in remote areas for personal safety reasons. Indirect operated solenoid valves require a pressure differential to function (approximately 0.3 - 3.5 bar or 4.3 - 50.8 psi). The response time of a solenoid valve is defined as the amount of time needed for a valve to go from an open to a closed position or vice versa. Response time is crucial for shut-off solenoid valves working with inflammable fuels and oils. Direct operated solenoid valves have a response time of about 30 ms, while the response time of indirect operated solenoid valves can be up to 1000 ms or higher. The response time of the valve varies with different manufacturers and operation types; hence it is vital to estimate the value while choosing a solenoid valve for the oil and gas industry.

- Fluid temperature and ambient temperature: Ensure that the valve materials can withstand the particular application's minimum and maximum temperature requirements. Most valves are rated for a minimum working temperature of -400C (-400F) , hence they can be installed outdoor in extreme cold climates. The valve can be mounted in any position without affecting its operation; however, mounting the valve vertically with coil upwards is highly preferred. Temperature consideration is also essential to determine valve capacity as it affects the viscosity and flow of the fluid.

- Solenoid power supply: Solenoid valves can work on AC or DC voltages. Read our article on choosing an AC or DC coil for a solenoid valve for more information.

- Approvals: Ensure that the valve is appropriately certified depending upon the application.

- Degree of protection: Ensure the valve has the appropriate IP rating for protection from dust, liquid, moisture, and contact. This is particularly important when the valve is installed in harsh industrial environments for remote operation.

Applications

- Fuel and oil: A proportional petrol dispensing solenoid valve can handle a fluctuating flow of petrol proportional to the control input signal, frequently used for blending applications. A normally closed petrol dispensing valve is used in fuel dispensers. Also, these valves can be used for on-off control of fuel oils in industrial and commercial oil burners, furnaces, and ovens.

- Natural gas: Vehicles running on natural gas use solenoid valves to control the gas flow into the engine’s cylinders.

- Propane: Solenoid valves are used in forklifts running on propane.